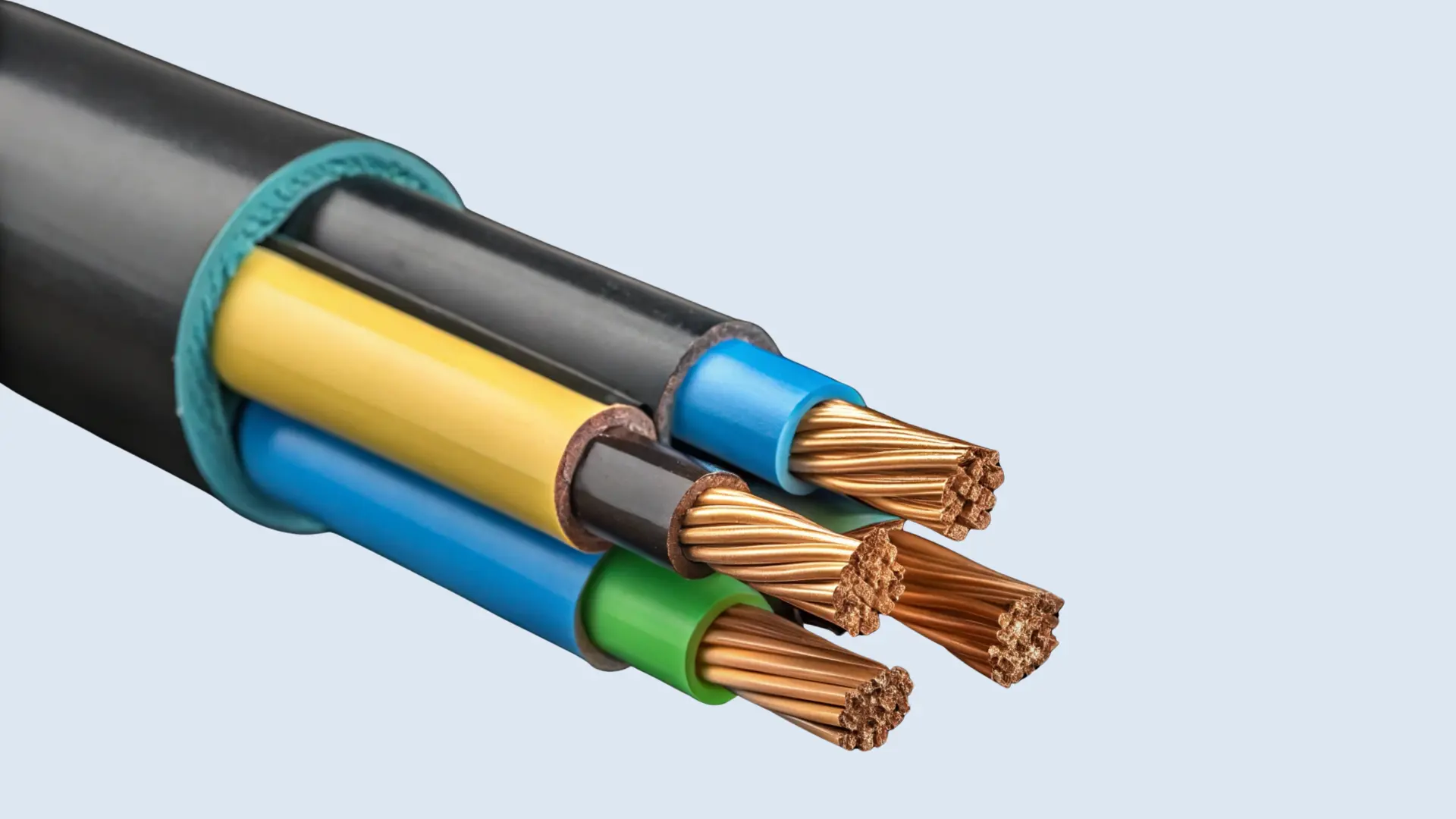

With the rapid growth of electric vehicles (EVs), energy storage systems, and charging equipment markets, the trend toward lightweight design has driven wire harnesses to withstand significantly higher voltage and power levels. Traditional harness applications have gradually increased to 600V, 800V, and even above 1000V. These changes impose stricter requirements on insulation withstand voltage performance, terminal structure design, and overall testing and verification standards. Under these conditions, ensuring that wiring harness designs comply with relevant standards such as UL 758 / UL 62, ISO 6722 / ISO 19642, and SAE J1654 / J1128 has become critical.

Why Must Wire Harness Products Comply with Safety Testing Standards Under These Trends?

Electric vehicles are governed by international standards such as ISO 26262 and IEC 61508; therefore, wire harness design must comply with stringent functional safety levels.

This compliance is achieved through three critical focus areas:

System-level perspective:

wire harnesses are no longer regarded as single components, but are evaluated as integral parts of the overall safety system.

End-to-end process optimization:

functional safety thinking must run through design, material selection, and verification stages.

Failure response capability:

the core design objective is to ensure that systems remain controllable and safe under extreme environments or failure conditions.

Wire Harness Dielectric Withstand Test Regulations and Requirements

With the widespread adoption of electric vehicles, high-power equipment, and industrial automation systems, the safety of wire harnesses operating under high-voltage conditions has become increasingly critical. To guarantee safety and quality, the industry now relies on hipot testing as a standard requirement throughout the entire manufacturing process. Its primary purpose is to ensure that products provide reliable insulation under actual operating conditions.

The main objective of dielectric withstand (hipot) testing is to verify the integrity of insulation between conductors, as well as between conductors and the housing or shielding layers within a wire harness. By applying a test voltage higher than the normal operating voltage, potential insulation defects can be identified at an early stage. This helps prevent issues such as leakage current, dielectric breakdown, or short circuits during service, thereby reducing the risk of electric shock to personnel and damage to equipment.

Different application fields are governed by their respective regulatory requirements. Commonly referenced international standards include:

IEC 60335 / IEC 60204: Safety requirements for industrial machinery and equipment

UL 758 / UL 62: Safety standards for wires and wire harnesses

ISO 6722 / ISO 19642: Automotive cable and wire harness standards

SAE J1654 / J1128: Automotive low-voltage and high-voltage wire harness specifications

LV 123 / LV 124: Test requirements for high-voltage systems in electric vehicles

Regarding typical dielectric withstand test conditions, the test voltage is generally determined based on the rated voltage and is commonly calculated as: Test Voltage = (Rated Voltage × 2) + 1000 V

The actual test voltage shall be adjusted according to the product type and the applicable standard. Test durations typically range from 1 to 60 seconds, with the objective of confirming insulation stability over a defined period. Pass criteria generally require no dielectric breakdown and no flashover during the test.

| Standard | Applicable Fields | Typical Test Voltage | Test Time |

|---|---|---|---|

| IEC 60204-1 | Industrial Equipment | (Rated Voltage × 2) + 1000V / 1500Vac | 1 s |

| IEC 60335 | Household Appliances | 1000–3000Vac | 1–60 s |

| UL 758 | Wires and Wire Harnesses | 1000–3000Vac or DC | 1 min |

| UL 62 | Power Cords | 2000Vac | 1 min |

| ISO 6722 | Automotive Low-Voltage Wires | 1000Vac | 1 min |

| ISO 19642 | Automotive Wire Harnesses | 1000–3000Vac | 1 s |

| LV 123 | EV High-Voltage Systems | ≥2500Vac or DC | 1 min |

| LV 124 | Automotive Electrical Systems | 1.5 × Rated Voltage | 1–10 s |

Overall, the wire harness industry is steadily evolving toward higher voltage capability, enhanced performance, lightweight design, automated manufacturing, and elevated safety standards. Correspondingly, advanced technical expertise and manufacturing excellence have become key indicators of competitiveness within the industry.