The global shift toward AI adoption is driving an evolution in server architecture, characterized by extreme power requirements and high-density configurations. This transition demands a smarter approach to electrical safety and production efficiency. In a previous article, we explored How Can Server Manufacturers Achieve International Electrical Safety Compliance Amid Rapid Innovation. However, once products enter the mass production stage, safety testing becomes not only a compliance requirement but also a critical factor directly impacting production efficiency and delivery stability.

As AI server technologies continue to advance, manufacturers commonly face the following three key safety testing challenges:

• Complex multi-point testing processes

• Heavy reliance on manual operations, increasing risks and errors

• Difficulty in managing test data

So how can manufacturers maintain both testing efficiency and compliance quality under the pressure of global mass production?

Associated Research Helps Server Manufacturers Optimize Safety Testing Efficiency

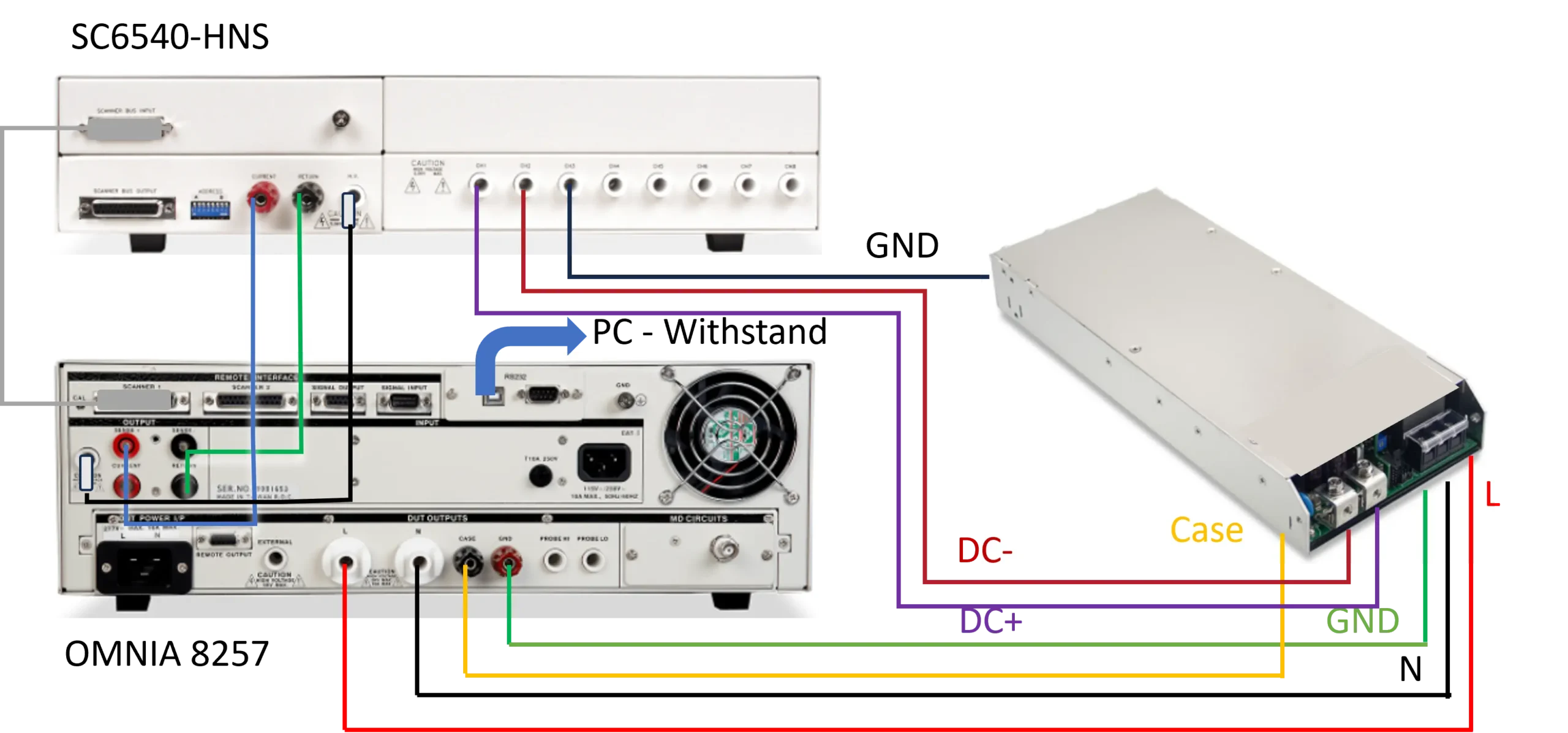

With 90 years of experience in global markets, Associated Research has long provided reliable electrical safety testing solutions to server manufacturers worldwide. These solutions help production lines maintain stable and efficient testing processes under high-load environments. Many manufacturers adopt the OMNIA 8257 paired with the SC6540 Multiplexers to effectively simplify multi-point testing and reduce human operation risks.

• OMNIA 8257: Supports ACW, DCW, IR, GB, RUN, and LLT testing, with built-in ACS (Adaptive Current System) functionality to meet diverse AI server safety testing requirements.

• SC6540 Multiplexers: Eliminate the risk of human error by replacing manual cable swapping with automated test point switching

• Withstand Control Software: Automatically stores test data, with options for cloud-based or local storage, improving data management and audit efficiency.

In addition, if multi-point testing is not required, Associated Research solutions can be reconfigured by adjusting test parameters or expanding system configurations to support “multiple DUTs (Device Under Test) simultaneously,” further increasing production throughput.

OMNIA II × SC6540 Successful AI Server Safety Testing Case Study

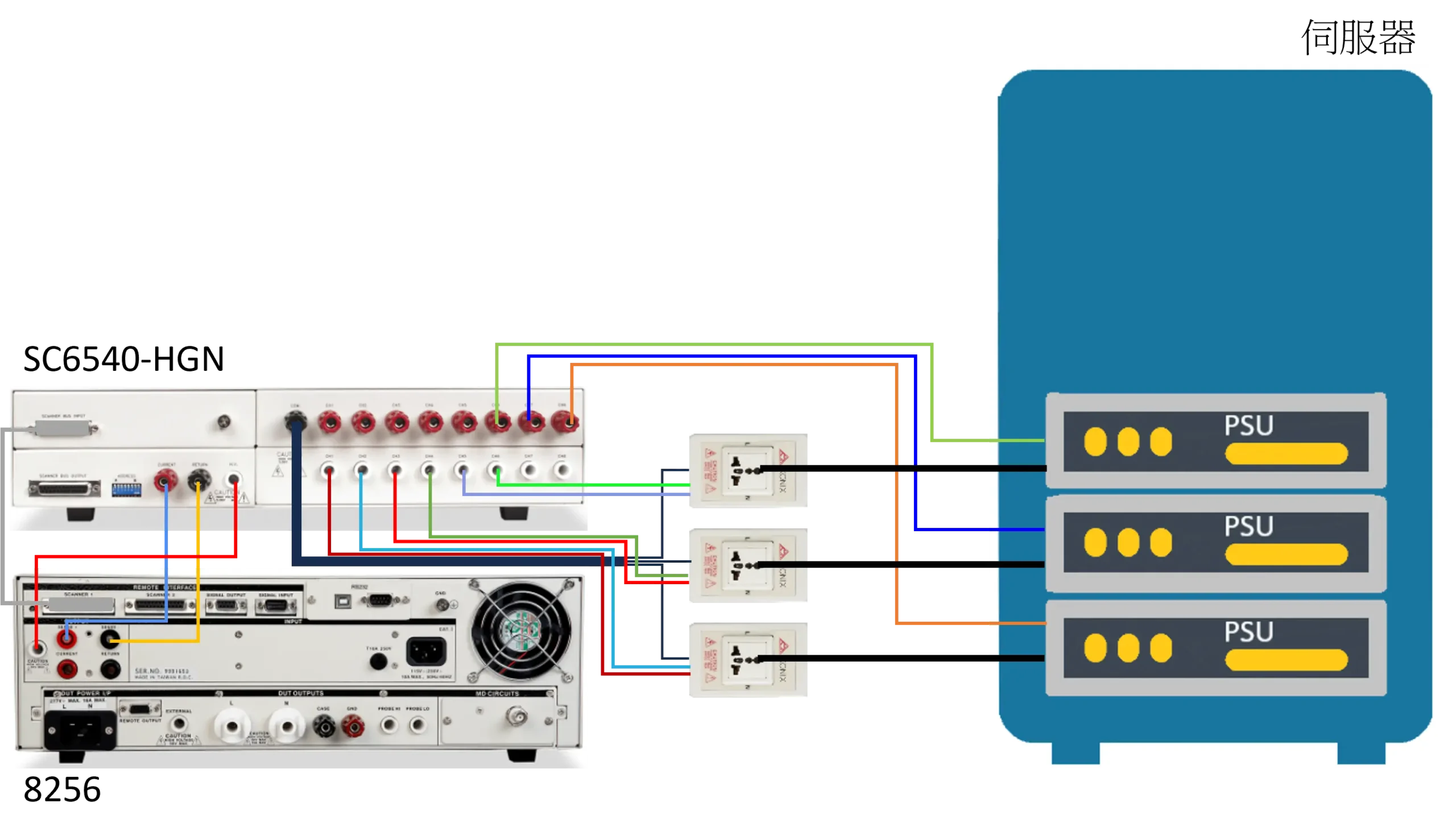

A leading AI server manufacturer required simultaneous DCW and GB testing across eight PSUs. By implementing a system configuration consisting of one OMNIA 8256 tester and two SC6540 scanners, the solution not only met all testing requirements but also significantly simplified the overall safety testing workflow, enabling the production line to successfully address mass production challenges.

(Image for illustration purposes only. Actual product specifications and configurations may vary according to production line requirements.)

Eliminate Safety Testing Bottlenecks and Build a High-Efficiency AI Server Mass Production System

Through proper integration of testing equipment and systematic management, server manufacturers can effectively reduce manual risks and testing complexity while transforming safety testing into a competitive advantage, laying a solid foundation for long-term AI server deployment.

Ikonix Asia is always ready to provide the most professional electrical safety testing solutions. Please feel free to contact us:

Website Contact: https://www.ikonixasia.com/contact-us/

Message us via WhatsApp: Ikonix Asia WhatsApp