A 5 min Read

The electrical vehicle (EV) is still the hot trends in recent years. Each car manufacturer is rolling out new models with futuristics advance technologies and performances to get customer’s attention. Take the latest Tesla Model S as an example, it has stunning power with more than 1,000 horsepower and be able go from 0 to 60 mph in less than two seconds. Behind all this, it relies on a powerful electric motor. Aside from increasing the battery capacity, the electric motor efficiency not only determines the performance in speed, also the mileage range.

With all the lavish features introduced and specifications, the safety requirement remains in highest protocol. Therefore, conducting electrical safety tests is necessary to ensure the electric motors meeting quality standards as well as the safety of the driver and passengers.

How to ensure the safety of electric motors?

Among many standards, UL 1004-1 (Rotating Electrical Machines – General Requirements) carries the most complete electrical safety test for motors. This may be different depending on the location. Hipot test, grounding test, and insulation resistance test for the material used are all required in this standard. The details of each test and requirement in the following:

Hipot Test

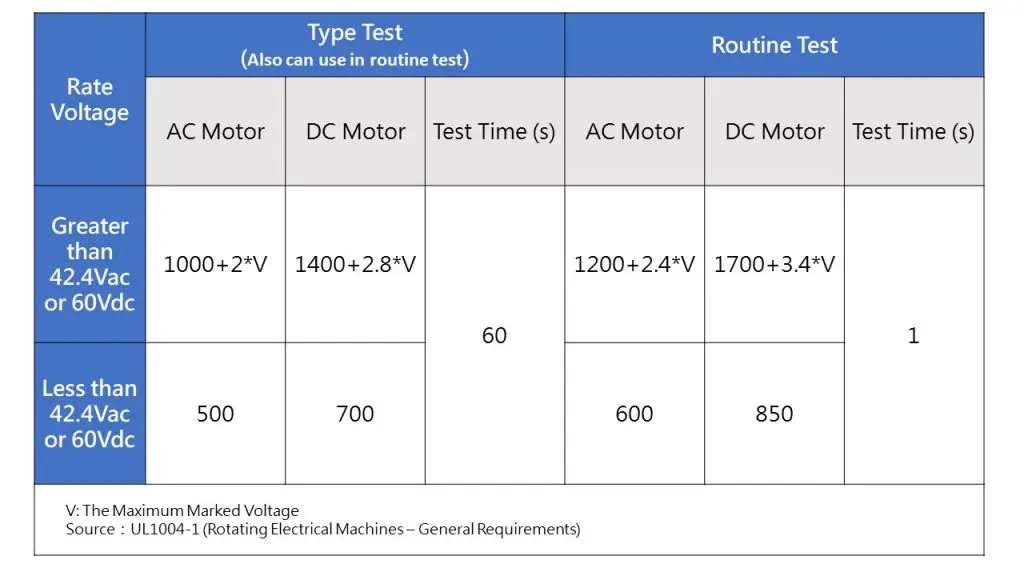

Electric motors operate in high voltage and temperature environments for a long period of time. The voltage may suddenly rise to exceed its rated voltage due to lightning strikes, false operation, malfunctions, etc. Therefore, a safe motor needs to pass strict tests to reduce the risk of equipment damage and the accidental electric shock to the driver and passengers. UL 1004-1 requires carrying out the Hipot test to check whether the electric motor can withstand the high voltage. According to the rated voltage of the motor and the test type, the requirements for the test voltage are different. In general, type tests and routine tests specifics further elaborates below (summary see table 1).

Type Test

When the rated voltage is greater than 42.4Vac or 60Vdc, the test voltage for the AC motor is 1000+2*the maximum marked voltage. And the test voltage for the DC motor is 1400+2.8*the maximum marked voltage. When the rated voltage is less than 42.4Vac or 60Vdc, the test voltage for the AC motor is 500Vac. And the test voltage for the DC motor is 700 Vdc. The test time for the type test is 60 seconds.

Routine Test

This can be the same test requirement as the type test. Or it can shorten the test time to 1 second by increase the test voltage. When the rated voltage is greater than 42.4Vac or 60Vdc, the test voltage for the AC motor is 1200+2.4*the maximum marked voltage. And the test voltage for the DC motor is 1700+3.4*the maximum marked voltage. When the rated voltage is less than 42.4Vac or 60Vdc, the test voltage for the AC motor is 600Vac. And the test voltage for the DC motor is 850 Vdc.

In addition, UL 1004-1 also requires to use the safety tester with a capacity of 500VA or more to ensure it has enough output current to test the motor accurately.

Table 1. A summary UL 1004-1 in Hipot testing.

Ground Test

To ensure fault current can flow to the earth terminal when motor under single fault condition, the UL 1004-1 requires perform the ground continuity test to avoid driver and passenger’s from getting an injury. This test is a routine test. The tester applies the maximum rated current to the earth terminal and measures the resistance between this point and the non-carrying electricity metal part. The resistance should less than 0.1 ohms.

Insulation Resistance Test for the Material

To prevent the fire and driver and passenger gets electrical shock and injury, the material use in the live part should pass the strict insulation test. Therefore, those material must be able to withstand 5000Vdc insulation resistance test.

Each Motor are Required to Pass the Strict Safety Test

Beyond the EV’s efficiency, the safety of motors is the most important area. Therefore, whether it is in the R&D or in production process, the motor needs to be tested and verified to enhance and ensure its safety. Ikonix has been an expert in safety testing and has assisted many motor manufacturers to solve their electrical safety test problems. We have the complete test solution to help you.

SE Series Electrical Safety Analyzer is the best electrical safety testing solution for the electric motor manufacturer. The Hipot test can reach 5kVac/6kVdc and insulation resistance test for material can reach up to 6kVdc. SE Series provides up to 32A to conduct the ground continuity test. It also has 500VA maximum output provides to handle large electric motors. Further, the SE Series features not only meet the UL 1004-1 safety testing requirements, the built quality and accuracy are few of many key reasons making SE series being the number one choice safety tester among leading manufacturers.

Aforementioned, there are many motor-related standards. The motor used in the EVs differs from the automaker and in different purposes. We will continue to introduce you to different motor safety standards and the corresponding solutions. If you can’t wait to learn more, you can take a look at our electrical motor industry application paper or contact our sales representative to learn more about motor electrical safety testing solutions.

Issue 16 – May 2021

Ikonix monthly e-Newsletter that provides rich and intelligent content covering latest company news, electrical testing insights, solutions and applications. Happy Reading!

About Ikonix

For 80 years, Ikonix has been producing cutting-edge electrical safety testers and AC power sources for a variety of industries. We strive to earn our customers’ trust by consistently offering dependable products, services, and reliable support for all testing applications.