We have entered the third year of COVID-19, and some governments decided to coexist with the virus and have conditionally agreed to ease restriction and embrace the recovery. By looking back on the economic effects of the pandemic, the production line had suffered a sharp drop in productivity due to a shortage of manpower. Simultaneously, the new anti-epidemic life stimulates the demand for technology products such as personnel computer, healthcare, and automobiles. The result of chip and component continue shortage that further caused a considerable impact on the global manufacturing industry. In response to the recovery, manufacturers optimize their production line. To ensure optimization meets satisfaction, the products’ safety and quality need to be scrutinized. For the industries mentioned above, Ikonix prepared three electrical safety solutions to meet the different optimization needs.

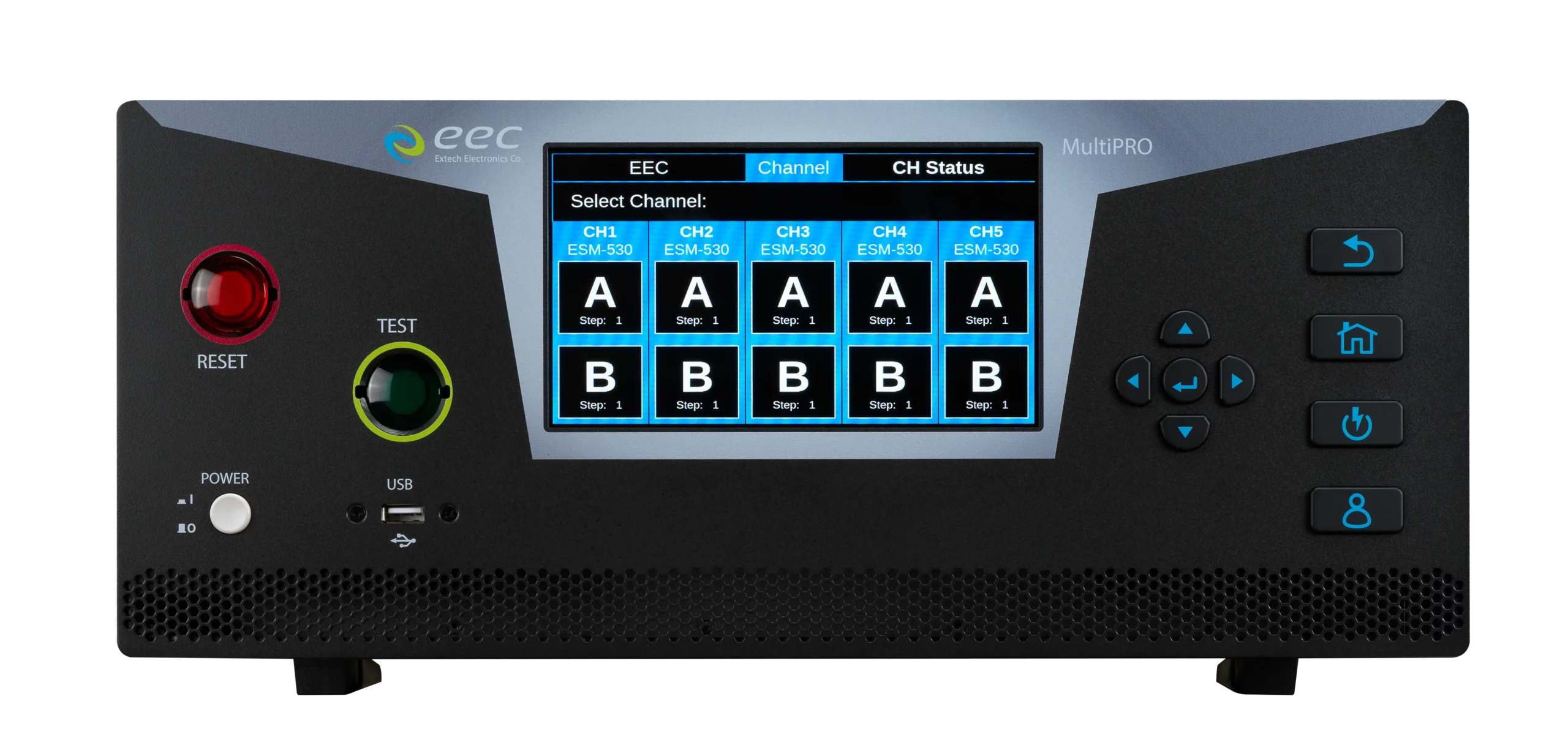

MultiPRO Optimizes Testing Efficiency and Quality for Semiconductor Industry

To accelerate resolving the global chip shortage issue, shortening the overall test time and maintaining quality is what manufacturers strive to do. The semiconductor component industry has large productivity and requires mostly to perform an Hipot test, ESM-500 MultiPRO Electrical Safety Platform is particularly suitable for this. The multi-functional modular design allows you to mix and match the best solution according to different standards’ testing requirements. The module function includes ACW or ACW+DCW+IR. Taking IEC 60747-5-5/UL1577 (Electrical Safety Standard for Optical Isolators) as an example, the production line generally uses 2.5KVac to 5kVac for the Hipot test (the testing voltage varied by their specification), so you can choose the ESM-510 module which provides up to 5kVac Hipot test voltage with 2 channels. The most commonly seen market solution on the production line is to test 10 components in parallel and determine the result by a group. But this testing method could cause many misjudgments or quality issues. By connecting multiple MultiPRO in parallel, a maximum of 100 DUTs can be tested synchronously. And each DUT is tested and determined the result independently. Our solution greatly reduces the probability of misjudgment and re-testing results optimizes testing efficiency. Further, the unique design of MultiPRO can effectively improve the test startup and connection speed, reducing the overall test time by 42%. In addition, the modular design of MultiPRO can quickly replace spare modules to eliminate malfunction, save maintenance and spare parts costs, and reduce production line downtime, ultimately lowering the TCO.

To accelerate resolving the global chip shortage issue, shortening the overall test time and maintaining quality is what manufacturers strive to do. The semiconductor component industry has large productivity and requires mostly to perform an Hipot test, ESM-500 MultiPRO Electrical Safety Platform is particularly suitable for this. The multi-functional modular design allows you to mix and match the best solution according to different standards’ testing requirements. The module function includes ACW or ACW+DCW+IR. Taking IEC 60747-5-5/UL1577 (Electrical Safety Standard for Optical Isolators) as an example, the production line generally uses 2.5KVac to 5kVac for the Hipot test (the testing voltage varied by their specification), so you can choose the ESM-510 module which provides up to 5kVac Hipot test voltage with 2 channels. The most commonly seen market solution on the production line is to test 10 components in parallel and determine the result by a group. But this testing method could cause many misjudgments or quality issues. By connecting multiple MultiPRO in parallel, a maximum of 100 DUTs can be tested synchronously. And each DUT is tested and determined the result independently. Our solution greatly reduces the probability of misjudgment and re-testing results optimizes testing efficiency. Further, the unique design of MultiPRO can effectively improve the test startup and connection speed, reducing the overall test time by 42%. In addition, the modular design of MultiPRO can quickly replace spare modules to eliminate malfunction, save maintenance and spare parts costs, and reduce production line downtime, ultimately lowering the TCO.

ESA Series One-stop Solution for Medical Electrical Safety Test

Through the Covid-19 epidemic, people have become more self-aware of their health. The demand increases on household medical devices, such as thermometers, blood pressure monitors, etc., to track their health status or arrange a physical examination to prevent diseases. To ensure there is no risk of the device for personal usage, electrical safety must be tested cautiously. Especially, when the medical device has close contact with medical staff and patients. If the leakage current is over the safety range, it will cause serious hazards. Therefore, it is necessary to carry out more comprehensive electrical safety tests with stricter requirements. IEC 60601-1 (standard of medical devices electrical safety) defines two insulation protection: Means of Operator Protection (MOOP) and Means of Patient Protection (MOPP). In addition, MOOP and MOPP have basic and double protection depending on the uses. Take a ventilator as an example, its operation is performed by medical staff and it has both external and internal power sources. Therefore, it must meet the double Mean of Operator Protection (2MOOP) requirements. The testing voltage is according to rated voltage and insulation protection. Based on our experience, the testing voltage is generally 2000KVac or 3000KVdc. The leakage current test can be divided into ground leakage current, touch current, patient leakage current, patient auxiliary current, and applied part leakage current. (To learn more about the IEC 60601-1 leakage current, please refer to issue 5.) The DUT should connect with a measuring device (MD) while testing. And the passing determination is also varied by types of leakage current. Except for the Hipot and leakage current test, medical devices also need to carry out the ground bond (GB) test. Medical devices have strict and complex medical device tests, so the ESA Series Electrical Safety Compliance Analyzer will be the best solution. It fully integrated AC/DC Hipot (ACW/DCW), insulation resistance (IR), AC ground bond (AC GB), ground continuity (GC), touch current (TC), and run testing (RT) features in a single solution. It also has built-in seven different human-body-simulation MDs to create a diversity of possibilities for replicating real-world conditions. The DualCHEK function enables simultaneous testing of Hipot (AC/DC) and GB to improve the overall production line testing efficiency. With an optional 500VA built-in AC power source, it is a one-stop solution of electrical safety testing for medical devices. For detailed testing information, simply follow up issue 13.

Through the Covid-19 epidemic, people have become more self-aware of their health. The demand increases on household medical devices, such as thermometers, blood pressure monitors, etc., to track their health status or arrange a physical examination to prevent diseases. To ensure there is no risk of the device for personal usage, electrical safety must be tested cautiously. Especially, when the medical device has close contact with medical staff and patients. If the leakage current is over the safety range, it will cause serious hazards. Therefore, it is necessary to carry out more comprehensive electrical safety tests with stricter requirements. IEC 60601-1 (standard of medical devices electrical safety) defines two insulation protection: Means of Operator Protection (MOOP) and Means of Patient Protection (MOPP). In addition, MOOP and MOPP have basic and double protection depending on the uses. Take a ventilator as an example, its operation is performed by medical staff and it has both external and internal power sources. Therefore, it must meet the double Mean of Operator Protection (2MOOP) requirements. The testing voltage is according to rated voltage and insulation protection. Based on our experience, the testing voltage is generally 2000KVac or 3000KVdc. The leakage current test can be divided into ground leakage current, touch current, patient leakage current, patient auxiliary current, and applied part leakage current. (To learn more about the IEC 60601-1 leakage current, please refer to issue 5.) The DUT should connect with a measuring device (MD) while testing. And the passing determination is also varied by types of leakage current. Except for the Hipot and leakage current test, medical devices also need to carry out the ground bond (GB) test. Medical devices have strict and complex medical device tests, so the ESA Series Electrical Safety Compliance Analyzer will be the best solution. It fully integrated AC/DC Hipot (ACW/DCW), insulation resistance (IR), AC ground bond (AC GB), ground continuity (GC), touch current (TC), and run testing (RT) features in a single solution. It also has built-in seven different human-body-simulation MDs to create a diversity of possibilities for replicating real-world conditions. The DualCHEK function enables simultaneous testing of Hipot (AC/DC) and GB to improve the overall production line testing efficiency. With an optional 500VA built-in AC power source, it is a one-stop solution of electrical safety testing for medical devices. For detailed testing information, simply follow up issue 13.

SE Series Strengthen Electric Vehicle Electrical Safety

Electric vehicles (EVs) have gradually become the mainstream of the car market. At the same time, it has driven the demand for automotive components and accessories, such as motors and batteries. These products rely on strong power. Therefore, to ensure the quality of EVs and the safety of drivers and passengers, they all need to meet the electrical safety standard requirements. (For further information, please refer to issue 25). Many customers in the EV industry choose the SE Series Electrical Safety Analyzer, a 4-in-1 safety tester consisting of ACW, DCW, IR, and AC GB. It meets the EV industry-related electrical safety testing requirement and is combined with the ARC detection function to further enhance safety. The 500VA maximum output capacity can handle batteries and drive motors that require high-capacity testing. Taking the charging plug as an example, the Hipot and IR test requires conducting multi-point testing on the poles. It can be further bundle with 7006 matrix scanners as a total solution to solve the complex wiring problem and improve test efficiency and production capacity.

The epidemic has brought a lot of changes to our lives and new challenges to each industry. Now, with post pandemic recovery, manufacturers must be well-prepared for the changes in the market and ensure the safety and quality of products. Ikonix has guarded global electrical safety for more than 85 years, devoted to the development and manufacturing of safety testing instruments and power sources. Actively cooperate with leading brands and laboratories to provide electrical safety test solutions for various industries ensuring electrically safe products.