Coronavirus disease (COVID-19) is an on-going pandemic. Forcing many firms in various of industries to close. Healthcare, on the other hand, are on huge demand. Aside from internationally recognized healthcare firms, many of the automakers and big techs are also joining in fighting against the virus by making the ventilators. Healthcare equipment is unlike any other electronic equipment as they used by both the operator and on patients. It has stringent testing regulations on products, especially on leakage current.

Figure 1 Patient Monitor for example. Although it does not touch the patient directly, yet, there are all kinds of vital signals are linked to the patient forming a loop, so that the product must be verified. This ensures the related electrical will not cause malfunction to other peripheral medical devices and result of affect the safety of the patient. Another example, the ventilator or respirator that directly contacts the patient. It is necessary to ensure minimal leakage current for safer operation.

As the pandemic quickly spread, Extech Electronics Co. (EEC) is fighting in parallel with international medical equipment firms on this new coronavirus (COVID-19). We are working with healthcare companies on the necessary equipment for the patient battling with this virus. In this article, it is the introduction of the most complex leakage current testing and standard in the medical safety fields. Further, examining the importance of leakage current testing or also called the touch current testing.

Figure 1. Patient Monitor

What is leakage current testing?

On any electronic device, there is an undesired current flow on the surface and through the insulation. Leakage current test as it measures the current that flows through a person if they were touching it. Thus, we can evaluate the quality of an insulation barrier on that device. There are many scenarios of “touching”, so when performing measurement, it requires to simulate on one spot or more accessible parts.

Leakage current testing is a must test for most of the electrical medical equipment. IEC 60601 is a board general standard on medical equipment. There is a wide array of medical products for various function. This standard consists of approx. 10 collateral and 80 particular standards [1] that addressed on each respectively. In a simple explanation. Particular requirement are for specific products or specific measurements built into products such as Electroencephalograms. When performing leakage current testing, the test generally checks on the earth leakage and enclosure leakage of the medical devices.

The testing on Leakage Current is important in electrical medical equipment, as it is to ensure that no electrical or functional failure shall pose an unacceptable risk to both patients and the operators. In many countries, electrical medical equipment needs IEC 60601-1 as a pre-requisite to commercialized the equipment.

Resistance in Human Body

Back in issue 1, we have introduced every human body have resistance to a certain level of electricity. Hence, we understand the limits can vary between people and environments. While IEC 479 stated the let-go current threshold value at 10mA. Which means the value that a human body can tolerate without a harmful effect. Yet, men have a different threshold than women on the perception and pain when they touched on the exposed electric current.

| Current | Physiological Effect |

| 0.5mA to 1mA | Perceived the current, tingling sensation |

| 5mA | Slightly feels and may start to response |

| 6-30mA | Painful shock and inability to let go |

| 30-150mA | Extreme pain, respiratory arrest, and possible death. |

| 10A | Cardiac arrest and severe body burns |

| For references, the maximum current of a USB charger is ranging from 500mA to 3A. | |

Figure 2. Human body resistance impedance value and physiological effects when electrical current flows into the body.

How to measure leakage line testing?

As mentioned, every human body has a resistance impendence value. To simulate the impedance of the human body under different conditions depending on the application of the product, the test is measured by Measuring Device (MD). The most common measurement taken under 110% of the rated input power in normal conditions and single fault conditions to simulate the worst-case scenarios. Also, reverse polarity test usually performs at the same time. As there are many types of products in the market, there are many MD designed for the different standard requirements.

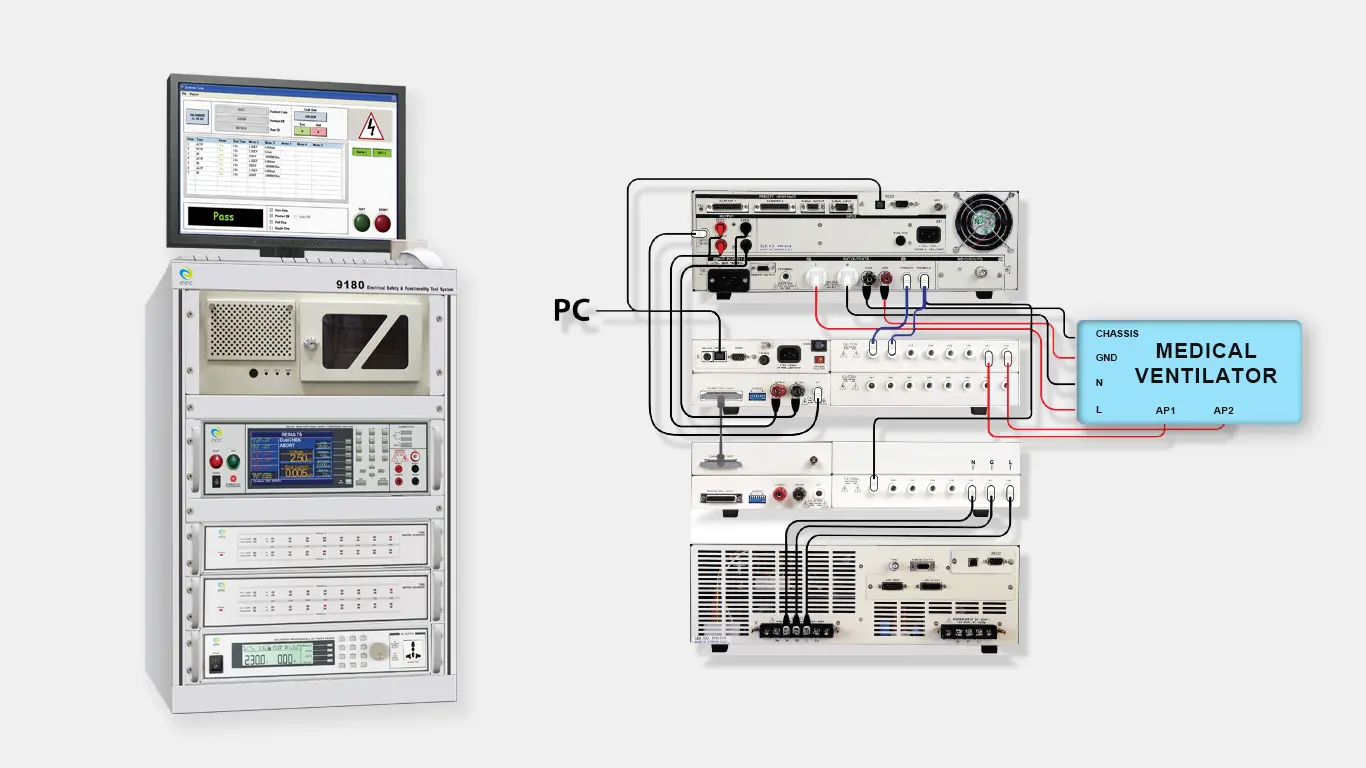

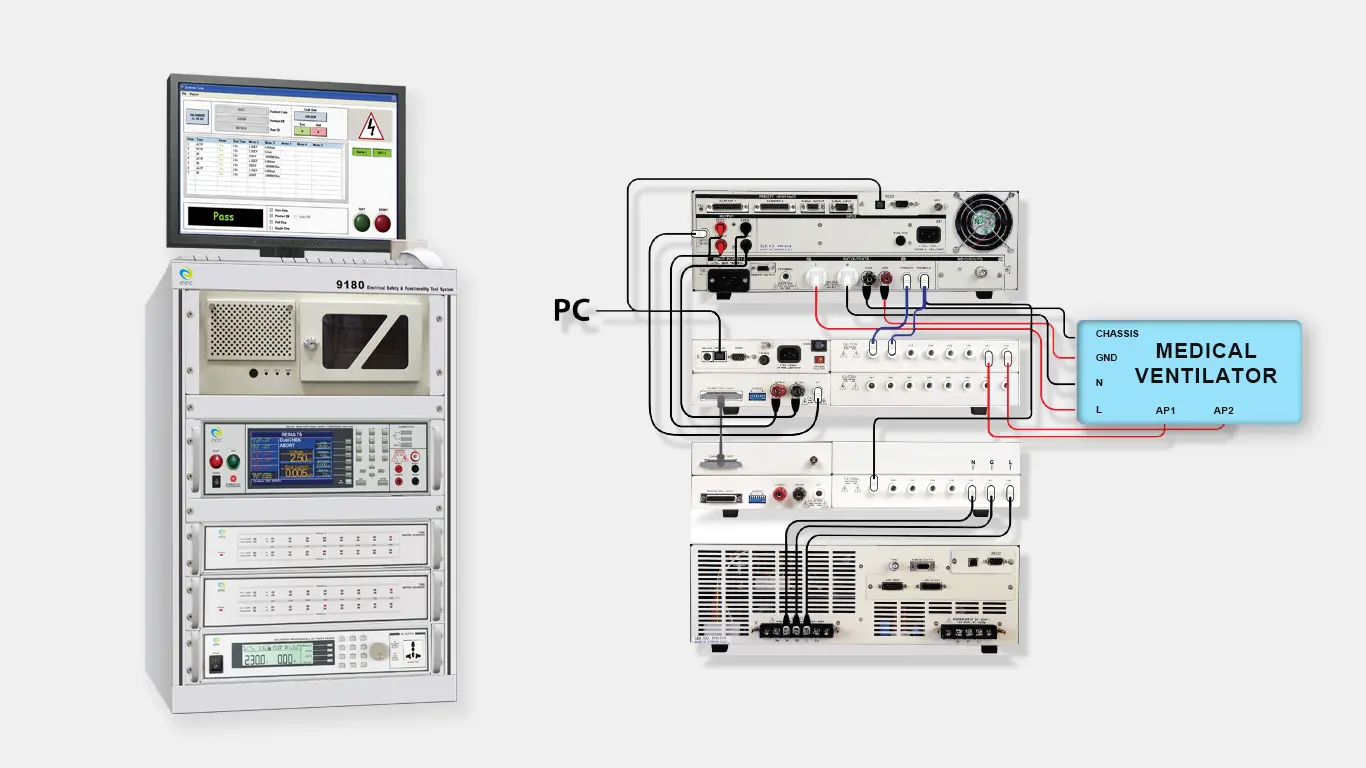

Most of EEC’s medical customer utilizes 7630 Touch Current Tester when testing on IEC 60601-1 standard. The instrument features seven different human-body-simulation measuring devices (MD) and eight different testing fault condition simulations. Create a diversity of possibilities for replicating real-world conditions. To optimize for the production floor. Our customer also bundling with ESA series electrical safety analyzer, SPACE-9180 safety software7006 Matrix Scanner and 6600 series programmable AC power supply into a complete medical safety testing system.

Figure 3. is the sample testing setup up for ventilator by interconnecting EEC flagship ESA series or 7630 Touch Current Tester with 7006 Matrix scanner to meet the best testing quality and efficiency.

Extech Electronics Co. (EEC) has over 40 years of experience. We have worked with many international leading test labs and medical equipment firms. On ensuring the quality of their product delivered to their frontline customers. EEC is fighting in parallel with international medical equipment firms on this new coronavirus (COVID-19). We are proactively working with these firms on the required equipment for the patient battling with this virus, including ventilators, air purifier, and other medical use equipment. Now, where medical firms are rushing on their production. We must put in place the quality of production with a more rigorous attitude to accurately control the health status of medical staff and patients.

Issue 4 – April 2020

Extech Explore is Extech Electronics Co. (EEC) monthly e-Newsletter that provides rich and intelligent content covering latest company news, electrical testing insights, solutions and applications. Happy Reading!

About EEC

For 40 years, Extech Electronics Co. (EEC) has been producing cutting-edge electrical safety testers and AC power sources for a variety of industries. We strive to earn our customers’ trust by consistently offering dependable products, services, and reliable support for all testing applications.