When Thomas Edison attempted to prove the danger of Alternating Current (AC) by launching a series of inhume smudging campaigns of electrocuting animals. It has successfully incepted onto people’s minds. In the movie “The Current War”, vividly illustrated how a hefty horse fall instantly when it engages AC. But, the query remains on how danger is AC or even how safe is Direct Current (DC) Edison imposes? Are we in a safer world where we surrounded by all kinds of electronic devices?

The Secret in a Human Body

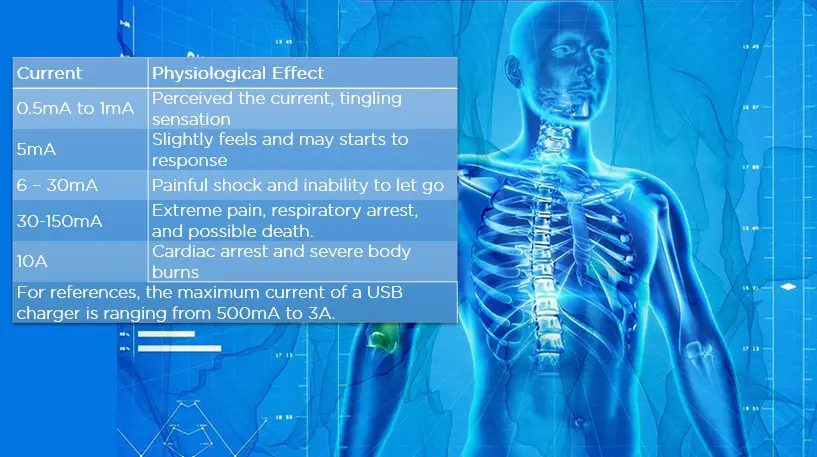

The human body have resistance to a certain level of electricity. This varies from person to person and environmental conditions. On average, the impedance is about 1,000 to 1,500 ohms. When current flow through the body, the skin provides the largest proportion of the body’s impedance value.

Figure 1. Human body resistance impedance value and physiological effects when electrical current flows into the body.

According to IEC479, the let-go current threshold value at 10mA. Which means the value that a human body can tolerate without a harmful effect. The key take away here is greater the current is, the greater the danger our human body affected.

The Hidden Danger in Our Day to Day Life

Today, electrical hazardous and danger continues to exist as infinite of electronics are available and uses everywhere. Electronics such as addicted mobile phones, computers, and home appliances. When the quality of these fails, injuries or possible risk of death. Figure 2 shows how poor-quality phone charger burnt and damaged household power supply, causing the fire. This type of news headlines aired across various of places.

What and how are the solutions offer today in protecting products that cost over millions and millions of dollars? The product must go through a series of tests before its shipment to ensure the safety, quality, and reliability of products.

Figure 2. Poor quality phone charger burnt down, the cause results of the fire. As these have shown over the news headlines. Photo Credit: Sina News, Souwan News and TVBS News.

What and How it Measures?

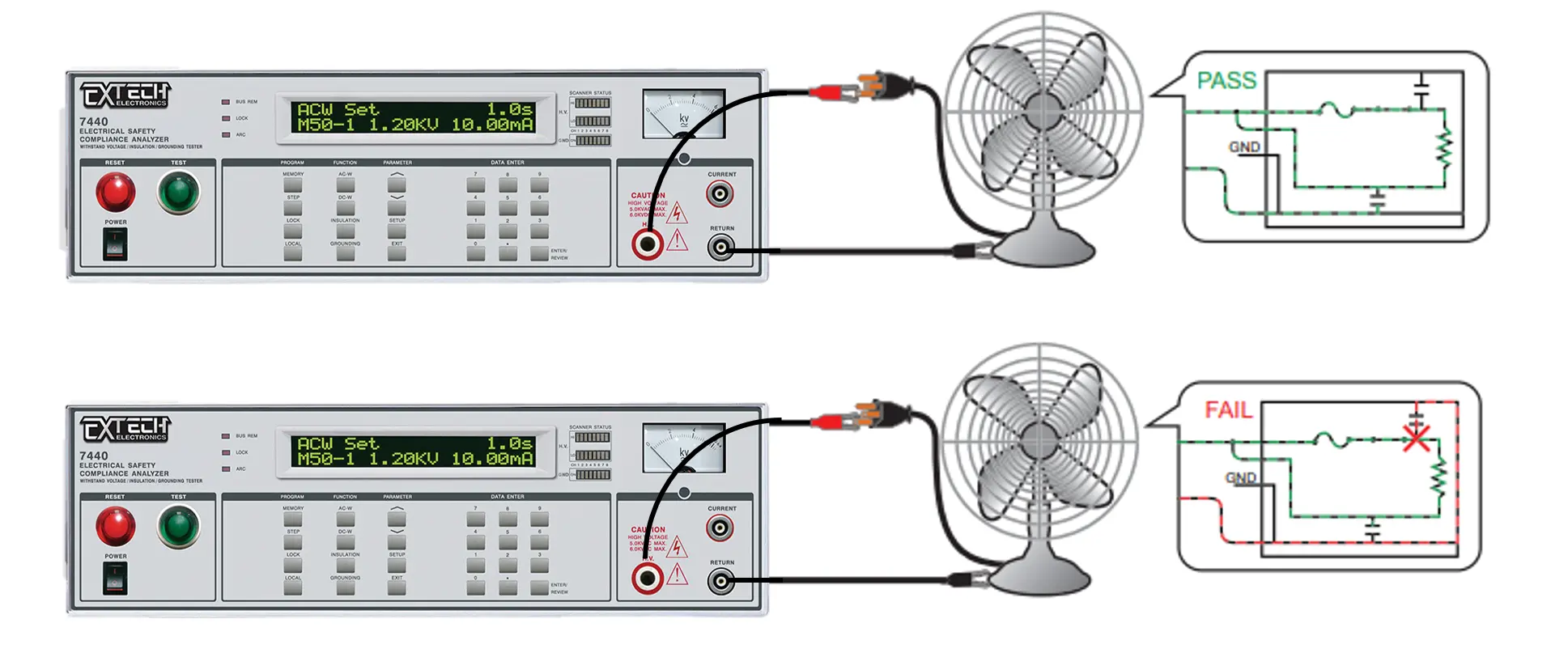

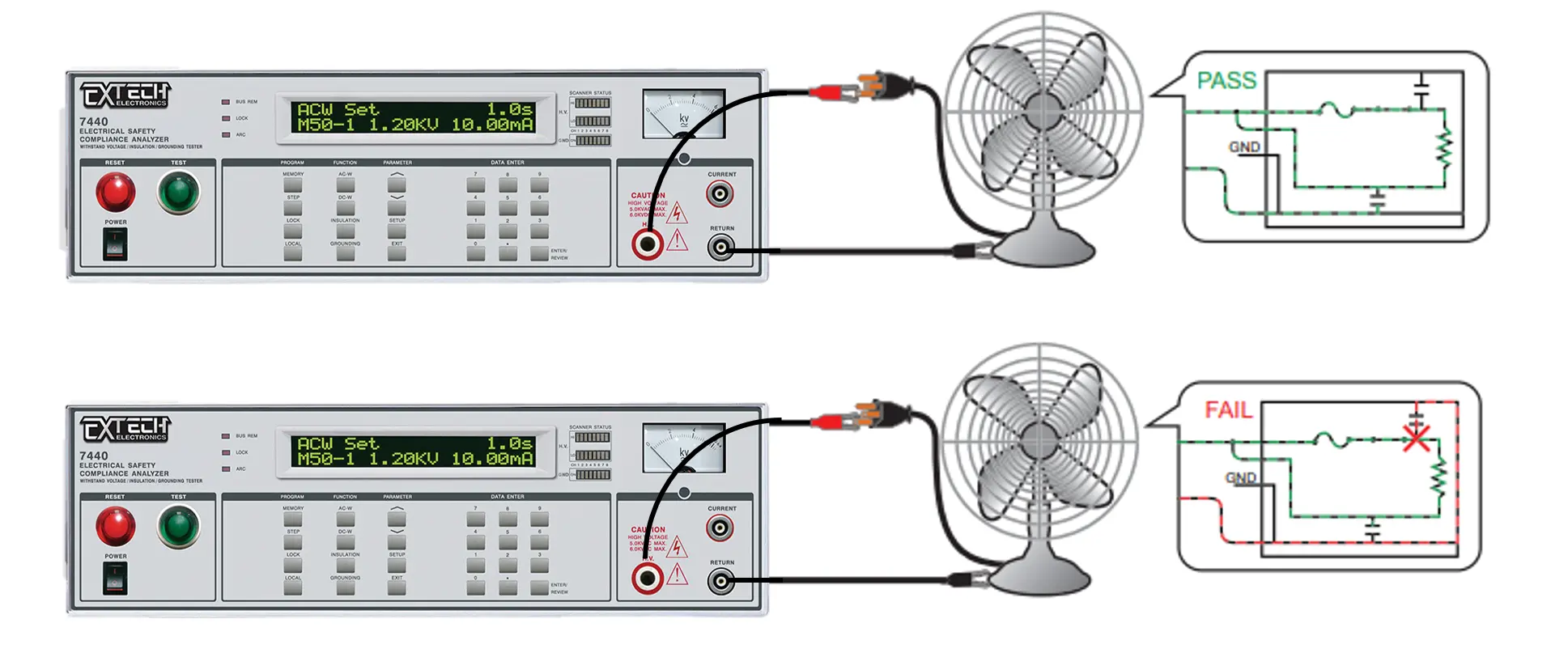

Figure 3. EEC legacy 7440 series 3-in-1 tester has been serving the safety testing line since 1996. Ensured top quality results in over billions of devices since then.

When the product may seem well designed and packed. How can one tell if the product is well insulated, or that is safe to use? It is hard to spot from the naked eye. Similar challenges the researcher and manufacture face in examining product quality. One of the common tests is Dielectric Withstand Test so-called Hipot test. Figure 3 are sample of how Hipot testing operates on an electric fan. By connecting the High-Voltage (H.V) to the Line and Neutral (L.N) and the Return to DUT shell. Failing the test of the product show electricity exposes on DUT shell, and is a danger to touch.

In a simple explanation, a Hipot test is by turning up the high-voltage or overvoltage. Ranging from 2,000V to 5,000V depending on Device Under Test (DUT) and testing conditions and standard requirements. While checking the current inside would not flow from one point to another. This method often used in verifying the quality outcome of the product is the same during the research and development stage and manufacturing process. Hipot test is capable of finding bad insulations, poor shielding quality on wires, any conductive or corrosive contaminants nearby the conductors, inadequate creepage and clearance distances and so on. As the result, it examines product quality in detail.

Learning from the Past and Apply for Better Future

As the industries progress with more variety and advanced technology. Their challenges on safety verification stringent at the same time. For example, when gasoline-based vehicles become electric-based. The isolation design of large and small material used in such vehicles becomes more important. Moving on to the medical industry, more and more wearables monitoring human health. The creation of such advanced technology requires considerations on the current and safety within. Which they have derived from the advanced and microscopic level power supply technologies.

Keeping up with such new technologies and rapid industry changes. Extech Electronics. Co. has the latest market insight, advanced technology through tens of millions of testing data, plus 40 years of experience. Our top-selling 4-in-1 SE Electrical Safety Analyzer provides enhanced safety features meeting today's industries and technologies' needs. SE series has been appointed by many international customers.

Figure 4. EEC next-generation 7400 series, the SE series 4-in-1 electrical safety analyzer, continuing on the testing legacy.

EEC has helped many of our customers to overcome and achieve the industry standards together with experienced sales and after service teams. With continuous improvements, EEC put our customers' solutions to safety the ultimate goal.

Issue 1 – January 2020

Extech Explore is Extech Electronics Co. (EEC) monthly e-Newsletter that provides rich and intelligent content covering latest company news, electrical testing insights, solutions and applications. Happy Reading!

About EEC

For 40 years, Extech Electronics Co. (EEC) has been producing cutting-edge electrical safety testers and AC power sources for a variety of industries. We strive to earn our customers’ trust by consistently offering dependable products, services, and reliable support for all testing applications.